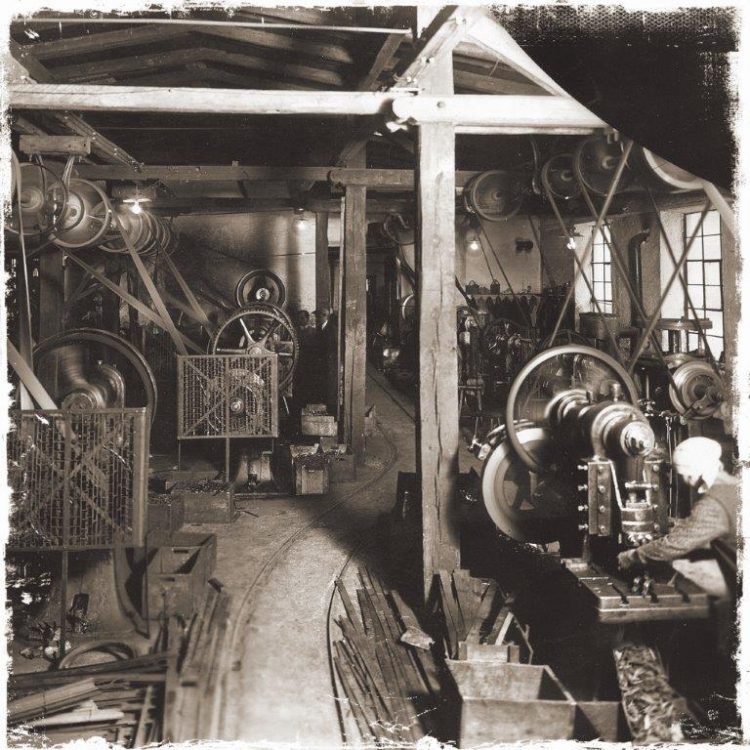

1896 Czech Eng. Špalek buys a mill and starts producing metal elements, including locks.

1908 The new owner is Anne Hartmann.

1909 The company is taken over by dr. Hermann Bessemer KREINISCHE EISENWAREN FABRIK G.m.b.H. and Stein.

1911/12 Among the TITAN workers we find the later president of the SFRY – JOSIP BROZA TITA.

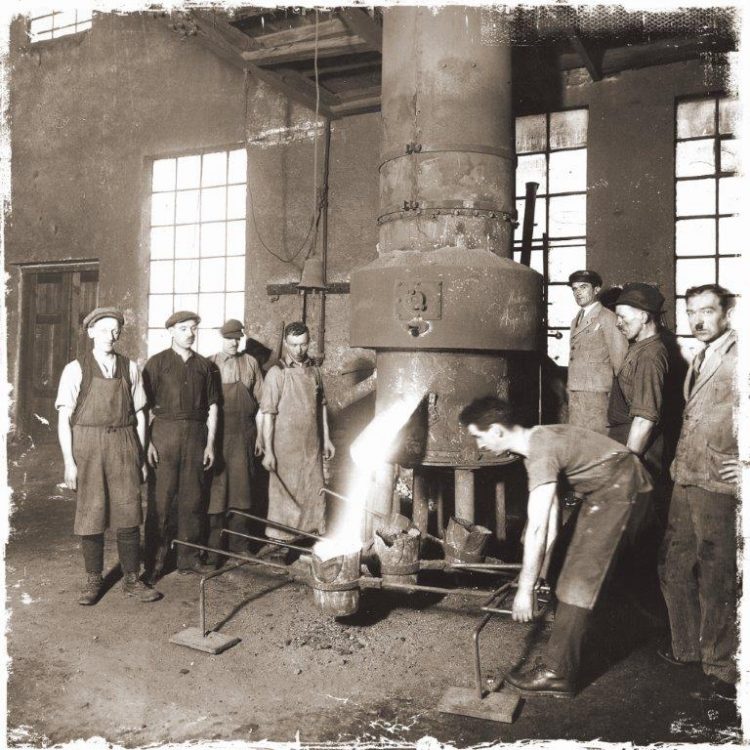

1919 Production of the first mortise locks and start-up of the foundry.

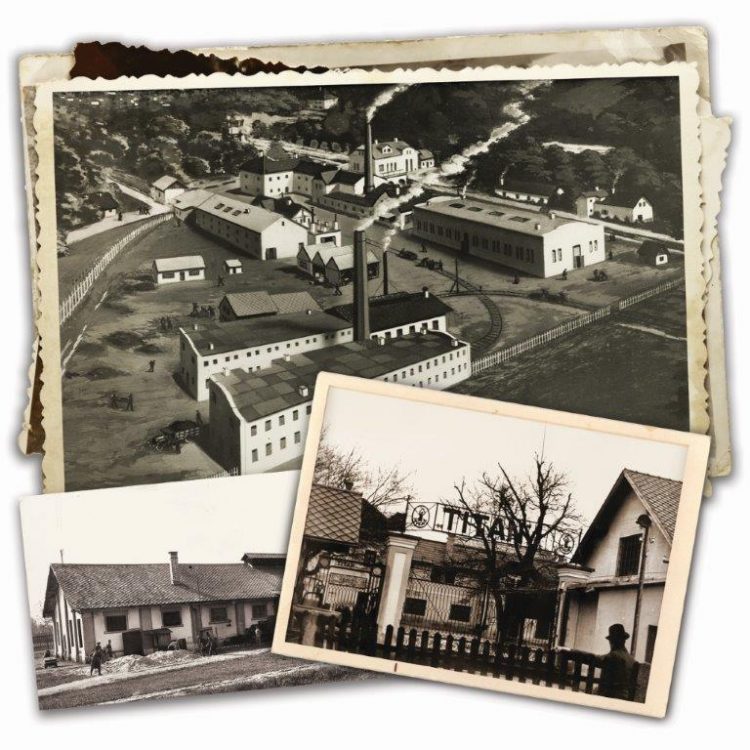

1920 The foundry starts operation at present location.

1922 The company is named “TITAN” CROATIAN JOINT STOCK COMPANY FOR IRON TRADE, Zagreb.

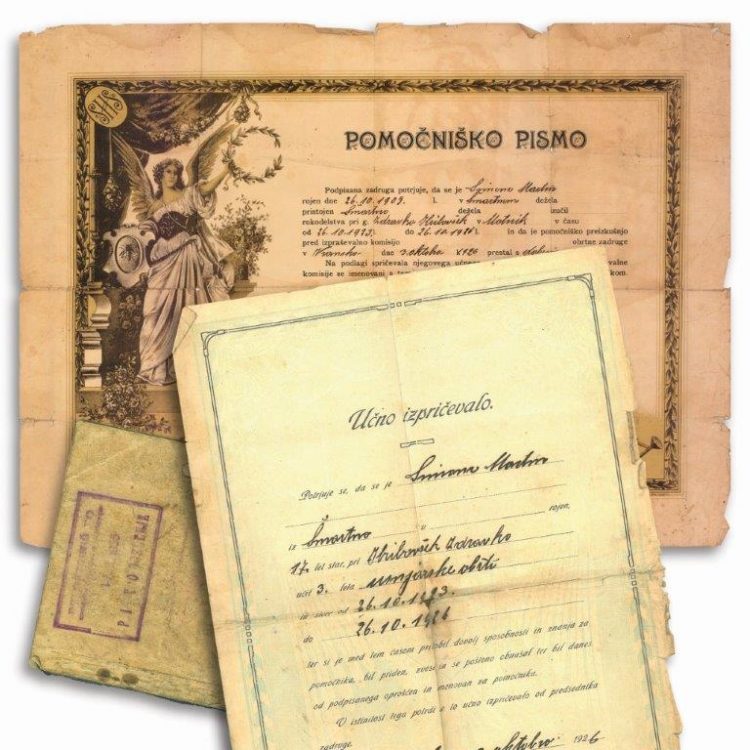

1925 The factory is bought by OLT from Osijek / Croatia.

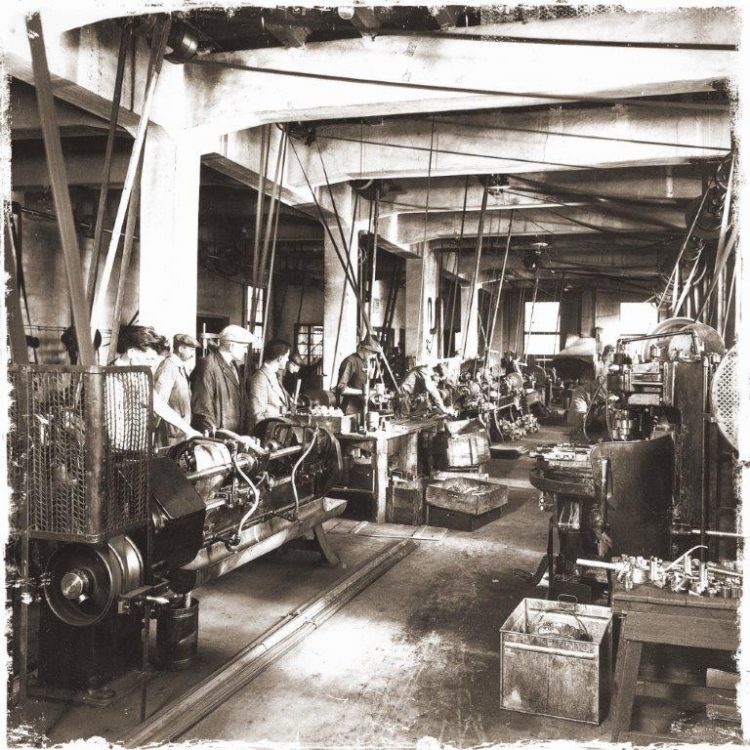

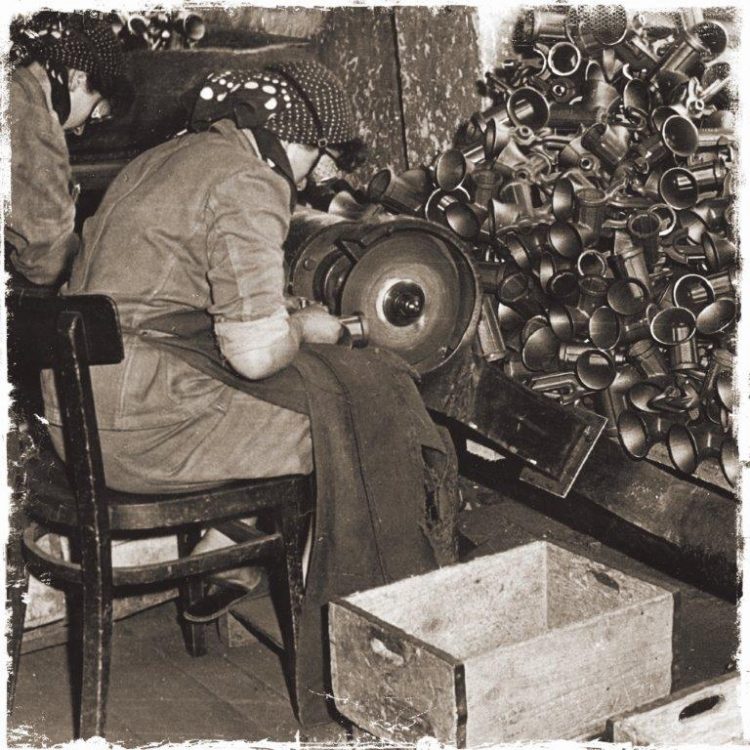

1933-1939 Production of door fittings, furniture locks, coffee grinders and meat slicers. In the years before World War II, the factory experienced leaps and bounds.

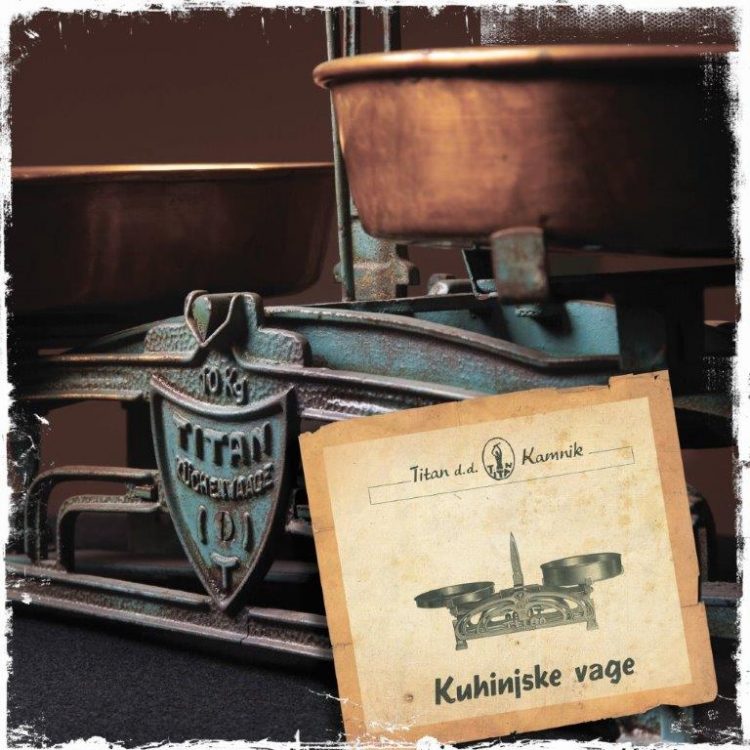

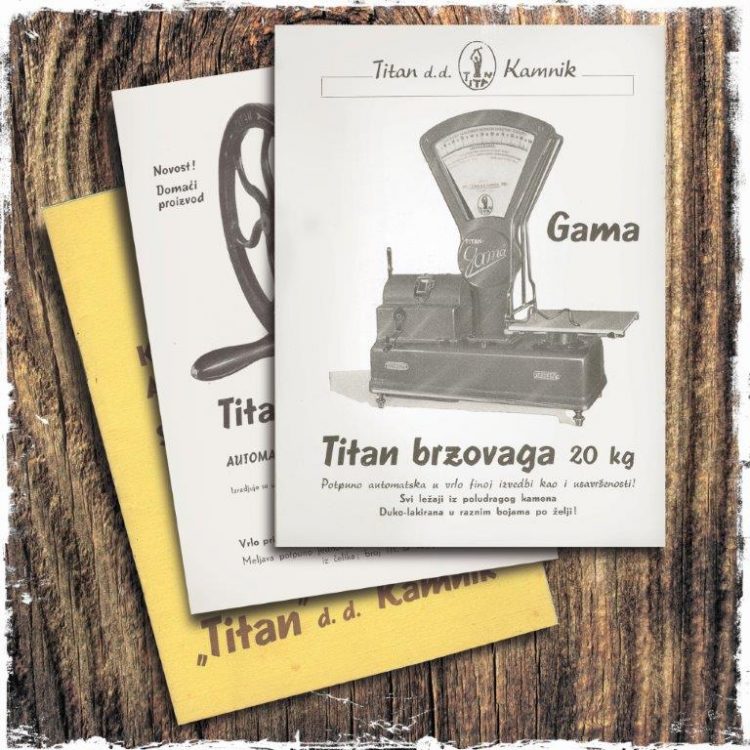

In 1933 The company shifted to the production of fittings, furniture locks, scales, weights and various household appliances. The factory survived the war unscathed and intensively continued the production of the aforementioned programs.

1945-48 TITAN becomes a state-owned enterprise in a socialist country.

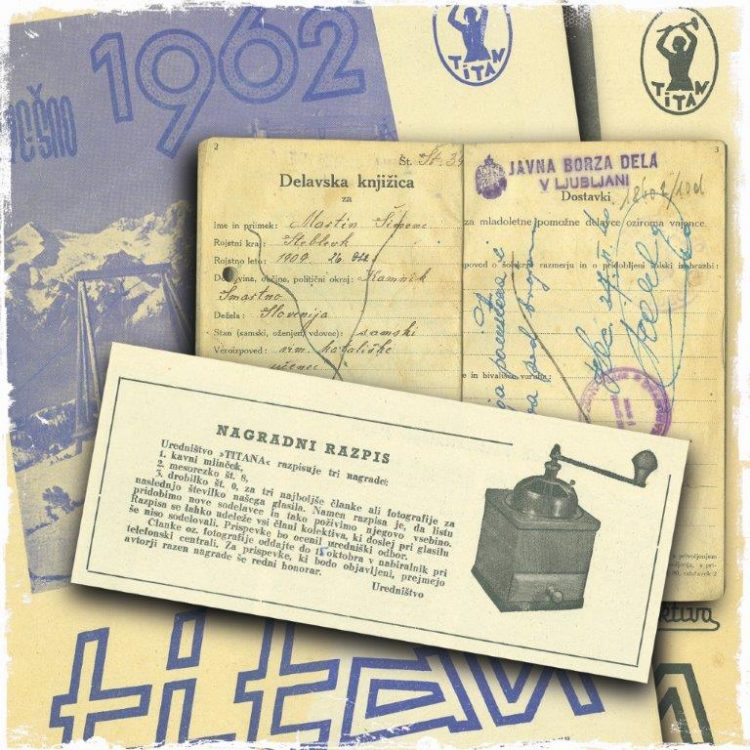

In the 60s The production program was finalized, which with minor changes forms the core of today’s Titan development: the foundry and cast iron processing were modernized and the production of cylinder locks began.

1962 Modernization of equipment and start of cylinder production. The first products for export.

1974 Launch of the first supercomputer (IBM).

1990 Beginning of the privatization process.

1995 We obtained the ISO 9001 certificate for the quality system, and the DIN certificate for cylinder locks for product quality, which enabled us to exist in conquered foreign markets and penetrate new markets.

1996 In accordance with the Property Transformation Act, TITAN is entered in the court register as a joint-stock company. At the same time, he was experiencing organizational and status changes.

2001 Casting off the foundry business. The foundry becomes a subsidiary of the Cimos business system and does business under the name CIMOS TITAN, livarna z obdelavo, d.o.o.

2004 Obtaining the ISO 9001:2008 standard.

2009 Obtaining an environmental permit.

2013/2013 We continued with the reorganization and optimization of CIMOS TITAN with the goal of long-term successful development.

2014 CIMOS d.d. is its 100% share in the company CIMOS TITAN, d.o.o. sold to current owner. At the same time, the name of the company was changed to LIVARNA TITAN, d.o.o.

2017 The first robot starts working in the company and with it new investments in automation and digitization of production.

2019 Purchase, installation and start-up of new INDUCTOTHERM melting furnaces, which enable stable and energy-efficient melt preparation.

2020 The company celebrates 100 years of foundry activity. Setting up a new warehouse for fittings.

2021 Start-up of a new transfer line for processing fittings, which drastically improves productivity and replaces a large number of older machines. Establishing the CSRE system for checking the energy efficiency of individual machines and controlling the consumption of key energy sources.

2023 Purchase of new machines for the production of cores according to the Croning process. Renovation of buildings after large-scale floods.

2024 Introduction of an automatic molding sand control system, which drastically improves the quality of the prepared molding mixture and reduces foundry waste. Business expansion in the field of aluminum forging and high-pressure casting.